Auto Upholstery Fabric

Auto Upholstery FabricAuto Upholstery Fabric

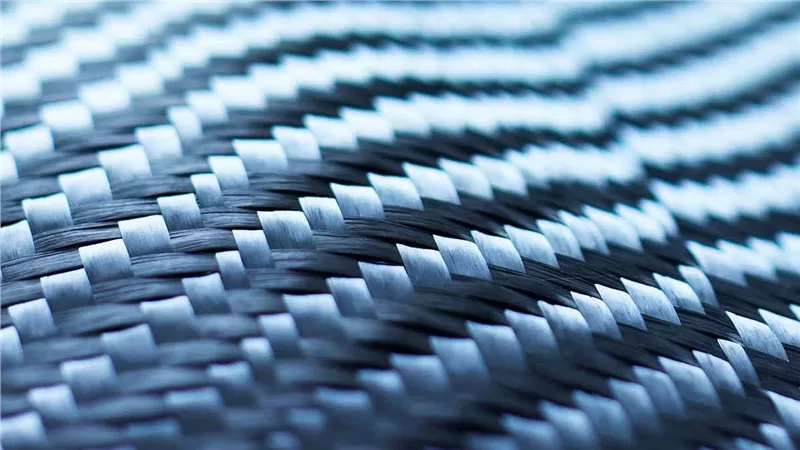

Fabric weaving is the process of creating a fabric by interlacing two sets of threads

Auto Upholstery Vinyl

Auto Upholstery VinylAuto Upholstery Vinyl

Artificial leather, also known as faux leather or synthetic leather,

Car Seats Covers

Car Seats CoversCar Seats Covers

Car seat covers are protective coverings designed to be placed over the seats of a vehicle to protect them from wear and tear,

Knitted Fabrics

Knitted FabricsKnitted Fabrics

Knitted Fabric

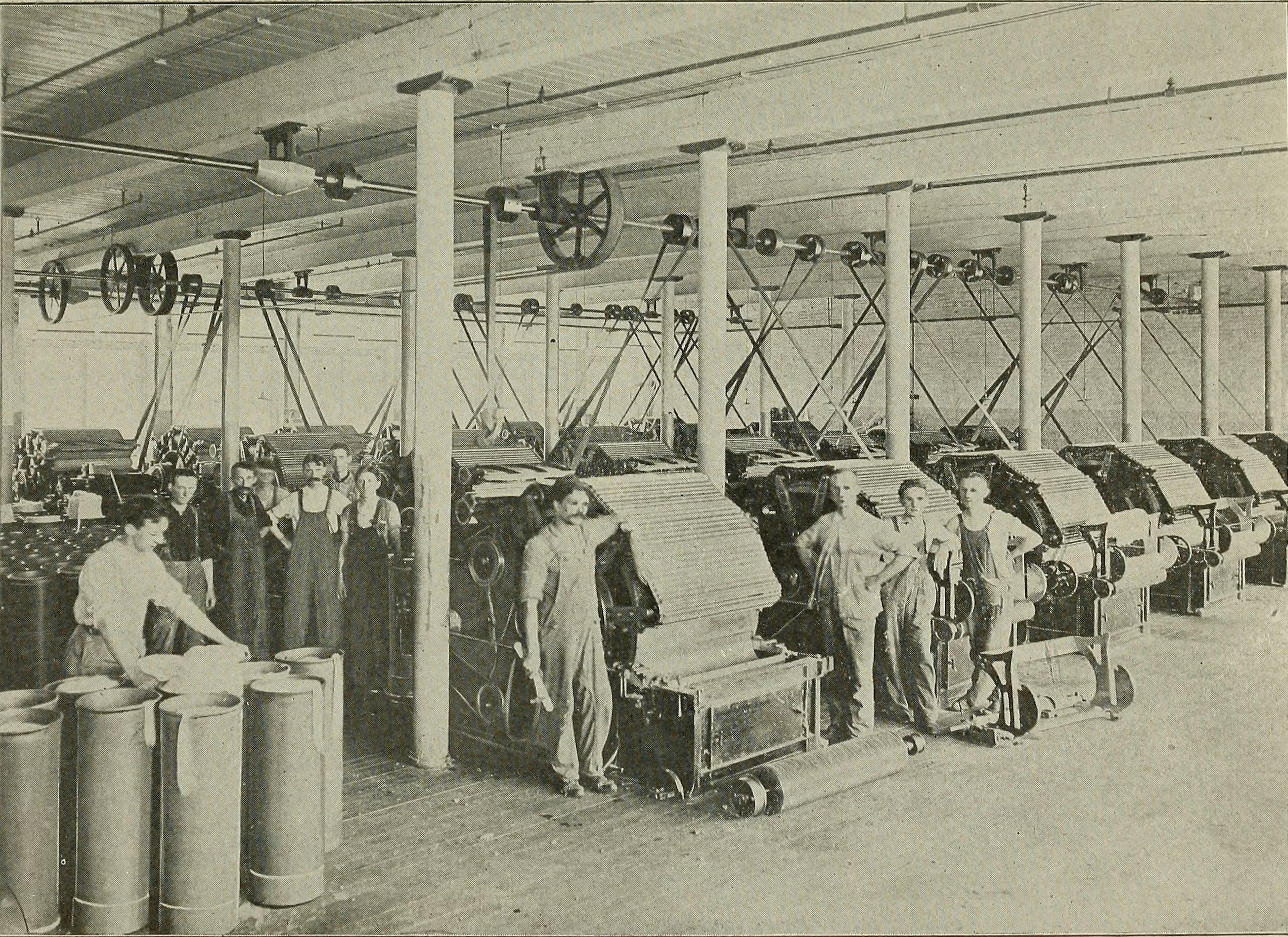

Flame lamination is a process used to bond two or more layers of fabric or foam together to create a single, thicker material. This technique is commonly used in the manufacture of automotive textiles, as well as in the production of home furnishings and apparel.

Flame lamination is a process used to bond two or more layers of fabric or foam together to create a single, thicker material. This technique is commonly used in the manufacture of automotive textiles, as well as in the production of home furnishings and apparel.

The flame lamination process involves passing the materials through a flame generated by a gas burner. The heat from the flame melts the surfaces of the materials, which are then pressed together under pressure to create a bond. The pressure and temperature of the process can be adjusted to control the strength and durability of the resulting bond.

One of the benefits of flame lamination is that it can be used to bond materials that are difficult to bond using other methods. For example, foam materials can be bonded to a variety of fabrics using flame lamination, which is not possible with other bonding techniques such as adhesive bonding.

Another advantage of flame lamination is that it can be used to create materials with a range of properties. For example, it is possible to bond materials with different densities to create materials with varying levels of softness and support. This makes it a versatile technique for creating custom materials tailored to specific applications.

However, there are also some limitations to the flame lamination process. For example, it can be difficult to control the temperature of the flame, which can result in uneven bonding or damage to the materials. Additionally, flame lamination can produce toxic fumes, which require careful handling and disposal.

Despite these limitations, flame lamination remains a popular technique for bonding fabrics and foam materials in the automotive, home furnishings, and apparel industries. Its versatility, strength, and ability to bond difficult materials make it an important part of the manufacturing process for a wide range of products.