Auto Upholstery Fabric

Auto Upholstery FabricAuto Upholstery Fabric

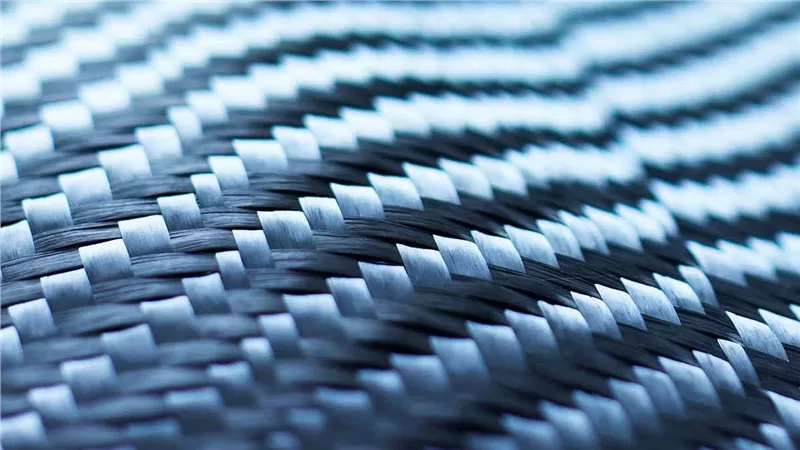

Fabric weaving is the process of creating a fabric by interlacing two sets of threads

Auto Upholstery Vinyl

Auto Upholstery VinylAuto Upholstery Vinyl

Artificial leather, also known as faux leather or synthetic leather,

Car Seats Covers

Car Seats CoversCar Seats Covers

Car seat covers are protective coverings designed to be placed over the seats of a vehicle to protect them from wear and tear,

Knitted Fabrics

Knitted FabricsKnitted Fabrics

Knitted Fabric

Fabric Weaving

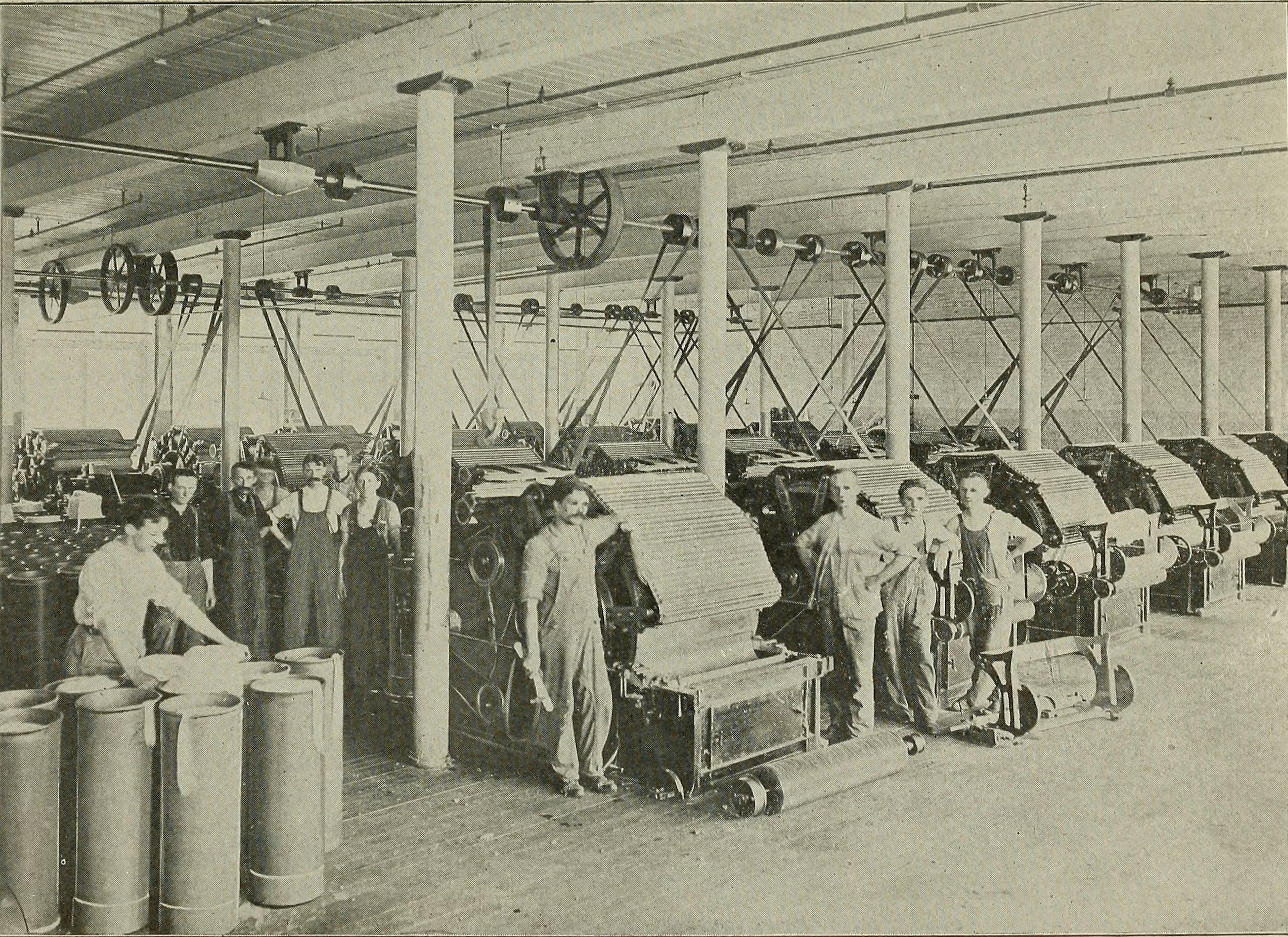

The Dornier weaving machine is a type of high-speed weaving machine that is commonly used in textile manufacturing. It was invented by a German engineer named Peter Dornier in the late 19th century and has since undergone several improvements and advancements.

The Dornier weaving machine is known for its ability to produce high-quality fabrics quickly and efficiently. It can weave a wide variety of materials including cotton, silk, wool, and synthetic fibers. The machine uses a series of warp and weft threads that are interlaced to create the fabric. The warp threads run vertically on the loom, while the weft threads run horizontally.

One of the key features of the Dornier weaving machine is its electronic control system, which allows for precise control over the weaving process. The machine can be programmed to weave specific patterns and designs, and can also automatically detect and correct errors in the weaving process.

Overall, the Dornier weaving machine is a highly advanced and sophisticated piece of textile manufacturing equipment that has greatly improved the efficiency and quality of textile production.

Fabric Weaving is a process of interlacing two sets of yarns or threads, known as warp and weft, to produce a woven fabric. It is one of the oldest textile production techniques, dating back to the Neolithic era. Today, fabric weaving is done using advanced machines that allow for faster and more precise production of high-quality fabrics.

The process of fabric weaving involves setting up a loom, which is a framework that holds the warp threads under tension. The weft threads are then passed through the warp threads using a shuttle or other mechanism, creating a new row of fabric. This process is repeated until the desired length of fabric is produced.

There are many different types of weaves that can be created using a fabric weaving process, each with its own unique characteristics and properties. Some of the most common types of weaves include plain weave, twill weave, and satin weave. The choice of weave depends on the desired properties of the fabric, such as its strength, durability, and appearance.

Fabric weaving is used to produce a wide variety of fabrics, including cotton, wool, silk, and synthetic fibers. The finished fabrics can be used for clothing, home textiles, upholstery, and many other applications. With advances in technology, fabric weaving has become faster, more efficient, and more precise, making it an important part of the global textile industry.